MANUFACTURING PROCESS

Combining Sun Ten’s manufacturing expertise with

modern equipment and strict quality control, we are able to produce the best

concentrated herbal extracts in the market. We are also fully experienced in

taking on contract manufacturing fully customized to meet your unique needs and

special demands.

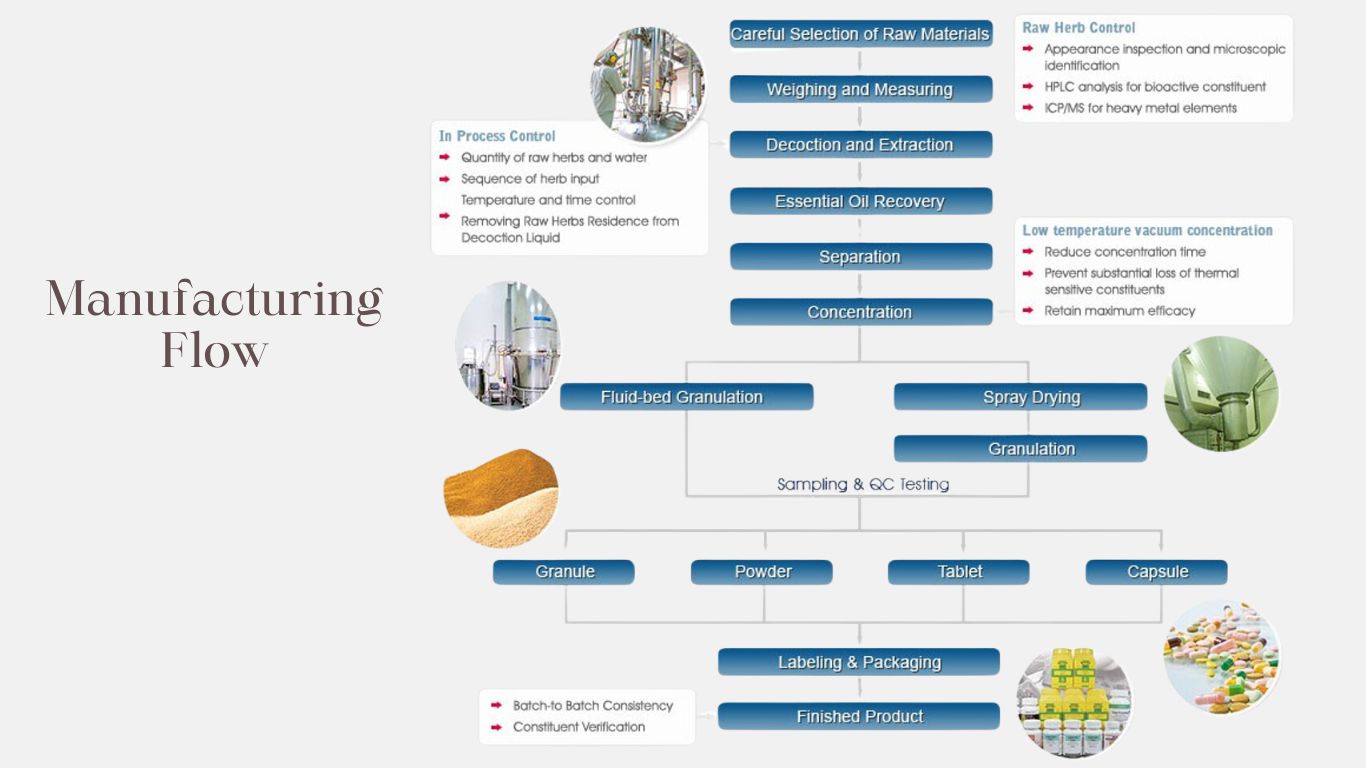

Manufacturing Flow chart

-

Process to retain the active constituents to optimize the products efficiency

-

The processes have been validated and each production batch is carefully documented.

Detailed Process

Raw herb materials are decocted in the traditional manner using water at a specified temperature for a defined time. Special considerations during the manufacturing process include:

- Quantity of raw herbs and water

- Sequence of herb input

- Temperature and time control

- Recovery of essentials oil

Water Extraction

Historically the majority of classical Chinese herbal formulas have been decocted with water. It offers excellent medicinal constituent extraction as a neutral solvent that does not alter the desired medicinal actions of the herbs. The water based decoction process draws out the desired medicinal constituents and optimizes the formulas unique character. Decocting all the ingredients of a formula together in water yields a final product that is synergistic refined and more potent that the sum of the ingredients if taken individually. Sun Ten uses only water based decoction methods for the entire manufacturing process.

Decoction Sequence

The sequence of the herbs within a decoction determines the efficacy of the formulas. For example, the rhubarb (da huang) in Rhubarb & Mirabilitum Combination (tiao wei cheng qi tang) must be decocted first, followed by the other ingredients to enable the formula to offer the therapeutic effect “harmonize the stomach and soothe the qi”. Comprehensive chemistries will change upon the sequence of herbal decoction. Sun Ten follows established sequence of decoction appropriate to each formulation because the desired efficacy of the final product depends on it.

Essential Oil Recovery

According to traditional Chinese herbal preparation methodologies, the handling of certain herbal medicinals is paramount to ensure efficacy. When preparing aromatic herbal medicinals by decoction, it is known that we must add the essential oil recovery procedure during the last few minutes of the decoction process. This is because prolonged exposure to the intense heat will damage and evaporate the essential oils that contain essential active constituents needed to deliver the desired medicinal effect.

When manufacturing at a large scale using pharmaceutical grade closed decoction procedures, handling herbal medicinals that contain sensitive essential oil necessitates an alternate, scientific procedure to retain essential oil. An estimated 23%-29% of the active volatile components are typically loss during the manufacture process. It was discovered by analyzing the constituents contained within recollected distillate that a majority of active constituents were lost. To prevent the loss of thermal sensitive constituents, a proprietary essential oil recovery device has been developed to retain the active ingredients and maximize the efficacy of the finished product. The essential oil based active constituents retained are verified by analytical verification.

Concentration

Low temperature vacuum concentration can prevent substantial loss of thermal sensitive constituents.

Granulation

Fluid- bed granulation, the final step of processing by transforming concentrated liquid to granules, is conducted with the addition of an excipient to stabilize the finished product.

Excipients

The use of excipients in Chinese herbal extracts is necessary to transform concentrated herbal extract liquid into the dry granule. The amount of excipients used in each product varies depending on the characteristics of the herbs within the formulation. Without the correct amount of excipient, the granules, once exposed to air, will absorb atmospheric moisture, clump together and become unstable. Sun Ten uses non-GMO free cornstarch as an excipient.

Spray Drying

The features of spray drying are using less excipients and effectively retaining active constitutes. The spray drying

products also proven to have better solubility, in other words, it can have better absorption for human body.